Universal Stepped Coupling

Popular Categories

- Ductile Iron Pipe Fitting

- 90°Double- Flanged Long Radius Bend

- All- Flanged Tee With 45°Angle Branch

- Bolted Gland Pipe Fittings

- Ductile Iron All Flanged Cross

- Ductile Iron All Flanged Tee

- Ductile Iron All Socket Tee

- Ductile Iron Double Flanged Bend-11.25°

- Ductile Iron Double Flanged Bend-22.5°

- Ductile Iron Double Flanged Bend-45°

- Ductile Iron Double Flanged Bend-90°

- Ductile Iron Double Flanged Duck foot Bend-90°

- Ductile Iron Double Socket / Socket Spigot Bend-11.25°

- Ductile Iron Double Socket / Socket Spigot Bend-22.5°

- Ductile Iron Double Socket / Socket Spigot Bend-45°

- Ductile Iron Double Socket / Socket Spigot Bend-90°

- Ductile Iron Double Socket Tee With Flanged Branch

- Ductile Iron Flange Socket

- Ductile Iron Socket-Spigot Tee With Flanged Branch

- Flange Spigot

- Flanged Bell mouth

- Ductile Iron Flanged Reducer

- Bolted Gland Bend

- DISMANTLING JOINT

- FLANGE

- UPVC DUCTILE IRON PIPE FITTING

- PIPE JOINT

- REPAIR CLAMP

- VALVE

- Ductile Iron Pipe

- RUBBER SEALS

Latest Post

Universal Stepped Coupling

Follow Our Social Media

Detail

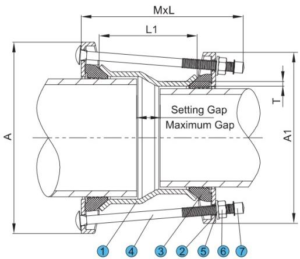

Universal Stepped Coupling

◆Material Specification:

| No. | Parts Name | Material | Specification |

| 1 | Center Sleeve | Carbon Steel | S235JR |

| 2 | End Ring | Ductile Iron | GGG50 |

| 3 | Rubber Gasket | Rubber | EPDM |

| 4 | Bolt | Dacromet Coated Steel | ISO898-1:1999 |

| 5 | Washer | Dacromet Coated Steel | |

| 6 | Nut | Dacromet Coated Steel | ISO898-2:1992 |

| 7 | Cap | Plastic |

◆ Dimensions(mm)

| Size Range |

Diameter |

Sleeve |

Setting Gap |

Max Gap |

MxL1 |

|||||

| Small End | Large End | |||||||||

| Min | Max | Min | Max | A1 | A | L1 | T | |||

| 59 | 72 | 68 | 84 | 165 | 180 | 115 | 4.5 | 25 | 50 | 4-M12x190 |

| 59 | 72 | 88 | 103 | 165 | 185 | 115 | 4.5 | 25 | 50 | 4-M12x190 |

| 68 | 84 | 88 | 103 | 180 | 185 | 115 | 4.5 | 25 | 50 | 4-M12x190 |

| 88 | 103 | 109 | 128 | 185 | 225 | 115 | 4.5 | 25 | 50 | 4-M12x190 |

| 109 | 128 | 132 | 153 | 225 | 250 | 115 | 4.5 | 25 | 50 | 4-M12x210 |

| 132 | 153 | 159 | 182 | 250 | 275 | 125 | 4.5 | 25 | 50 | 4-M12x220 |

| 159 | 182 | 192 | 210 | 272 | 305 | 125 | 5 | 25 | 50 | 4-M12x220 |

| 192 | 210 | 218 | 235 | 305 | 315 | 135 | 5 | 25 | 50 | 4-M12x230 |

| 218 | 235 | 242 | 266 | 315 | 350 | 135 | 5 | 25 | 50 | 4-M12x230 |

| 242 | 266 | 272 | 289 | 350 | 395 | 135 | 5 | 25 | 50 | 6-M12x230 |

| 272 | 289 | 315 | 332 | 395 | 450 | 135 | 5 | 25 | 50 | 6-M12x230 |

◆ Features

- DuctileIronGGG50(Mild Steel S235JR)material with FBE coated.

- Equippedwith Dacromet Coated Steel bolts,nuts.

- EPDMrubber seals.

- HighTolerance Mechanical Pipe Fittings

Enables the mechanical jointing of pipes made of different materials and of various outside diameters.china manufacturer.

Description

- Wide outside diameter range: an average of 21 mm by side.

- Small number of models for a Nominal Diameter.

- Reliability:

– Permanent leak tight joint when compressing the gasket

between the end-flange and the sleeve onto the pipe surface.

– Anticorrosion protection: epoxy powder coating (150 μm) and

Dacromet® 500 Gr.B for the bolts.

- Ease and speed of installation:

– Angular deflection ±6°.

– Absorbs expansion and contraction.

– Accommodates misalignment.

– Important setting gap.

- Conformity to standards:

– NF A 48-830: Foundry products – Spheroïdal graphite cast iron

fittings for PVC drinking water pipes under pressure.

– NF EN 545: Ductile iron pipes, fittings, accessories and their joints for

water pipelines – requirements and test methods.

– ISO 2531: Ductile iron pipes, fittings, accessories and their joints for

water applications.

- Approval:

– Drinking water approved.

- Nota:

This coupling does not resist to longitudinal forces and be sure

adequate restraint is provided to prevent pipes dislocation.

Technical data

- Range: DN 40/50 to 400.

- Maximal working pressure: PN 16.

- Temperatures: +0°C to +60°C.

- Torque: 60 to 70 Nm.

Applications

- Drinking water networks.

- Pumping, treatment, water storage.

- Fire protection networks.

- Irrigation networks.

- Sewage networks and rain waters drainage

(WC type – EN 681-1).

Tests

- Sealing test according to standard ISO 2531.